- HMPP winding storage tank production line

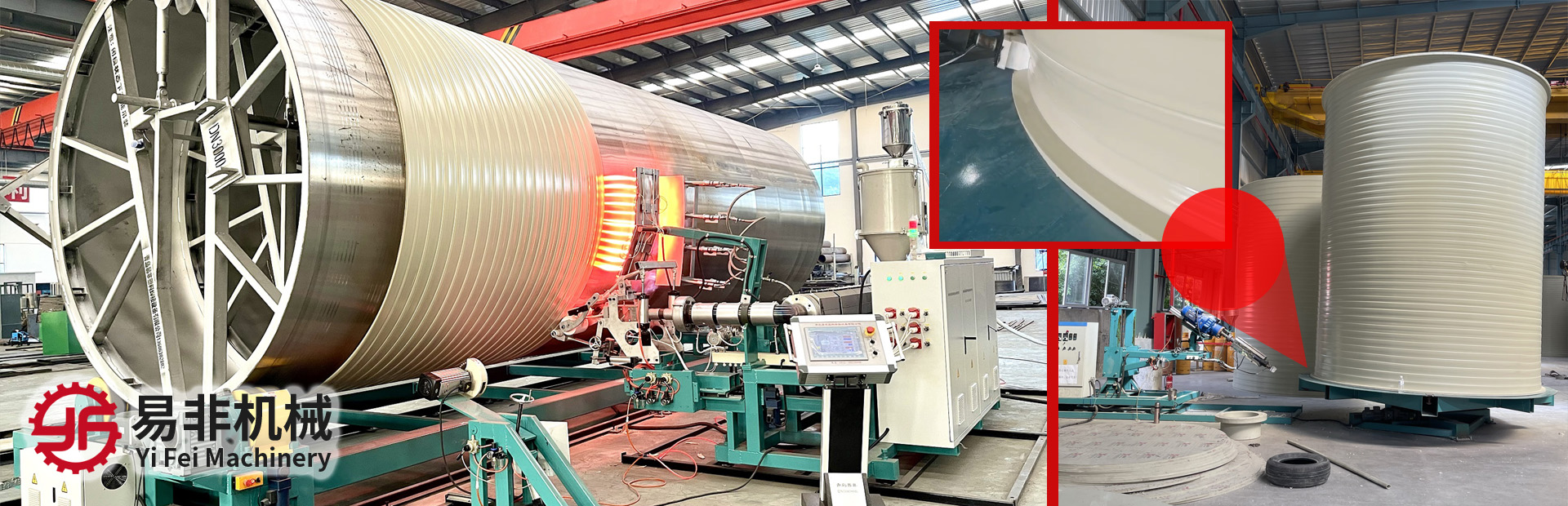

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

- Plastic tank punching and cutting machine

The plastic sheet welding machine is developed based on the principle of hot melt, and it is suitable for welding, assembling, rolling, and vertical welding of thermoplastic sheets. Plastic sheet welding has been transformed from manual to fully automated machine welding, without the need for welding rods. After heating, cooling, and pressure are set according to the thickness of the sheet, the sheet melts and self assembles. The interface is smooth and beautiful, with high strength, reducing labor costs and improving labor efficiency.

Processing thickness of 3-30mm, capable of producing specifications of 2-6 meters. The equipment can also be customized as needed, with a maximum thickness of 50mm. Optional configurations include right angle welding, PLC Siemens, etc.

Application scope: Manufacturing PP water tanks and containers, plastic equipment manufacturing, pipeline construction, ventilation systems, water treatment systems, spray washing towers, environmentally friendly chemical anti-corrosion electroplating, swimming pools and aquaculture ponds, laboratories, transportation and logistics industries.

ŌŚ?Applicable materials: PP, PPH, HDPE, PVC (A), etc