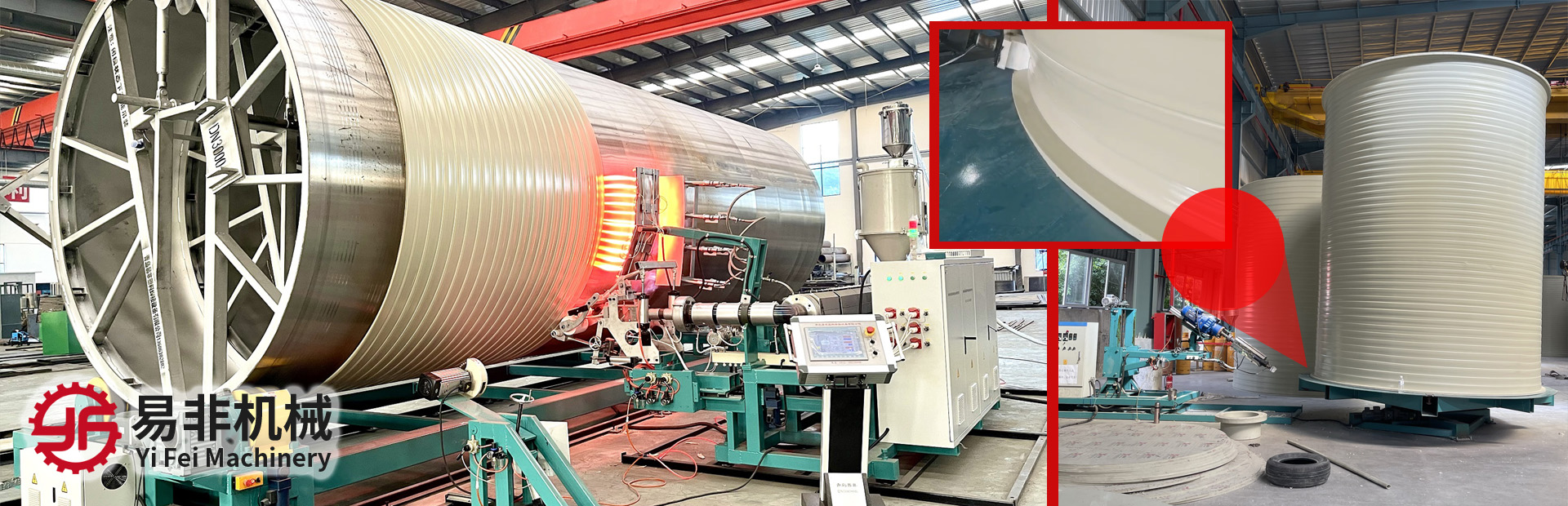

- HMPP winding storage tank production line

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

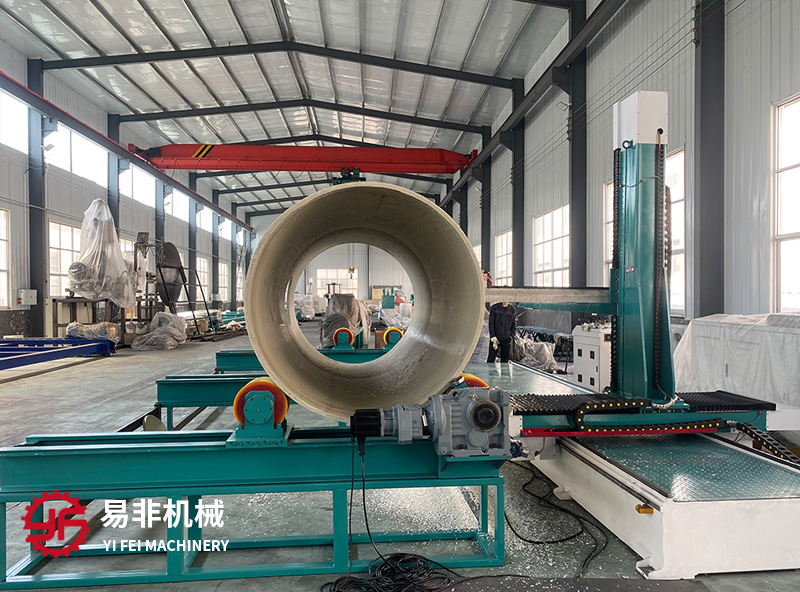

- Plastic tank punching and cutting machine

The plastic punching machine can be used for punching and cutting circular plastic products such as PPH/PP/HDPE plastic barrels, circular pipes, and tanks. The characteristic of this equipment is that it uses CNC software to draw cutting size graphics and other data, which can quickly and accurately cut large thick pipes, replacing manual cutting.

This machine is divided into two parts, the rotating platform and the cutting host. The rotating platform includes rubber rollers installed on the frame to support the tank body. The supporting rubber rollers include movable rollers and fixed rollers. The distance between the movable rollers and the fixed rollers is adjusted by a motor to accommodate tanks of different sizes. The frame is made of high-strength structural steel welded and can support large plastic products.

The rotating platform is designed to be linked with the punching and cutting host, which can meet the continuous cutting of images of different sizes and positions on the tank body. The punching efficiency can be increased by about 6 times compared to manual labor. Can process plastic products with a diameter of 1-4.5 meters. Equipment specifications can be customized according to needs!