- HMPP winding storage tank production line

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

- Plastic tank punching and cutting machine

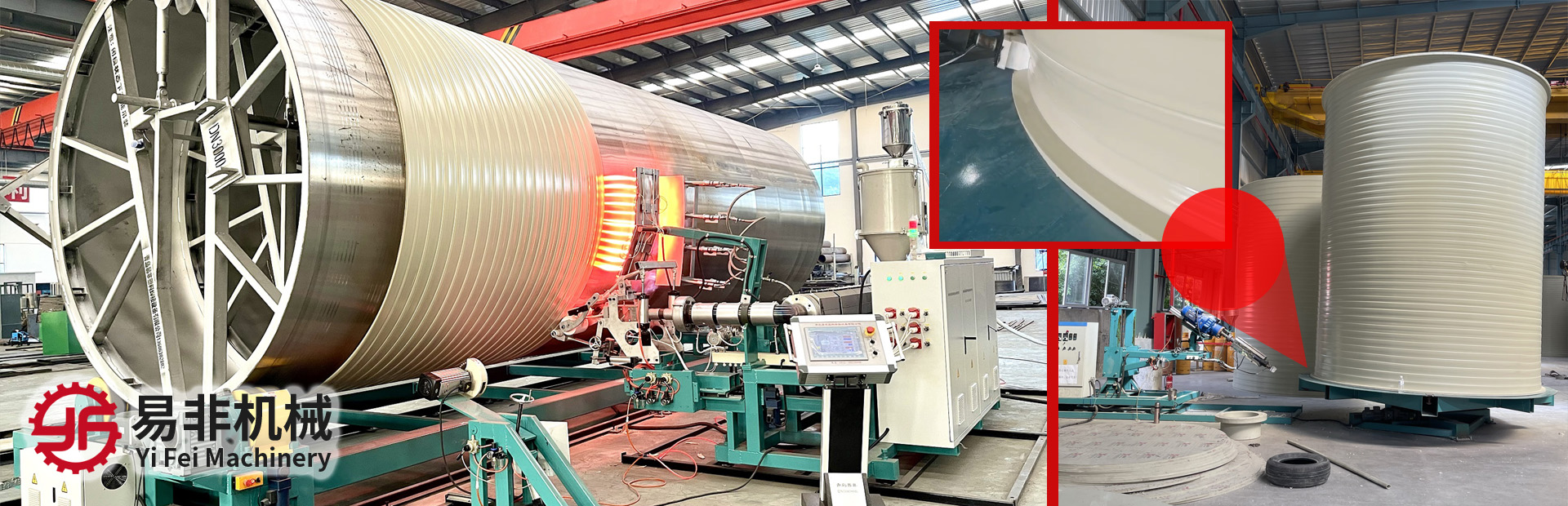

Description and characteristics of PP and PE plastic welding rod production lines:

PP and PE welding rod extrusion production lines are mainly used to produce high-quality plastic welding rods, which have the characteristics of high purity, strong adhesion, and good welding effect. Common specifications include circular 3mm-5mm and triangular (3 * 5, 4 * 6) double stranded welding rods. Mainly used for cracks in plastic products, storage tanks, and pipeline junctions.

Components of PE and PP plastic welding rod production line:

т?Composed of a 45 precision extruder, extrusion grinding tool, stainless steel cooling water tank, traction machine, and dual station winding machine.

Advantage feature

1. High precision: Due to the irregular and complex shape of the welding rod, it has a great impact on plastic molding. We use special materials and mold processing technology to ensure smooth and stable extrusion of plastic, ensuring high precision of the welding rod.

2. Stability: Welding rods require high stability in traction during the production line. Instability during horizontal transmission can lead to unstable welding rod dimensions. Our company uses a dual wear-resistant PU roller traction method to effectively ensure stability during the welding rod production process.

т?Applicable materials: PPуPPHуHDPE