- HMPP winding storage tank production line

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

- Plastic tank punching and cutting machine

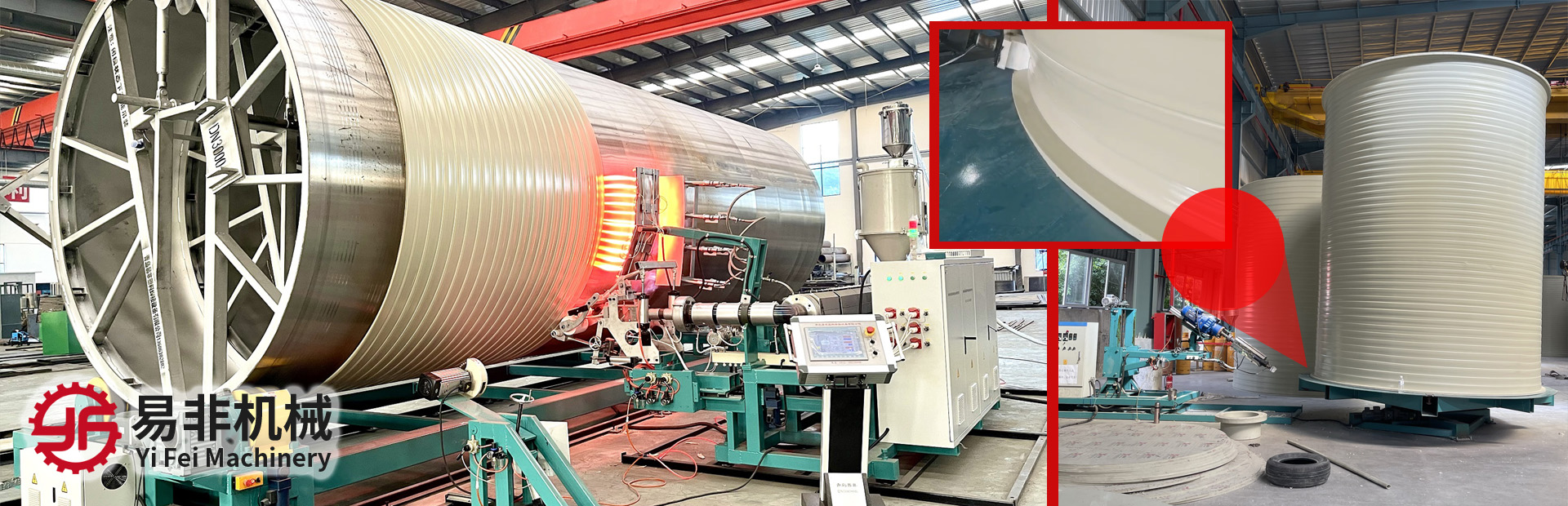

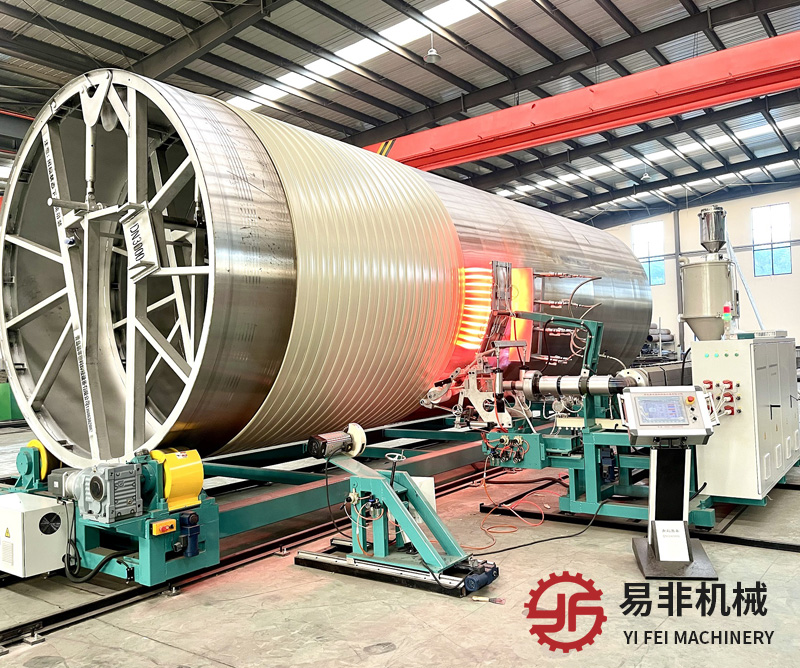

The forming process of PPH (PP/HDPE) winding tank production line adopts high-efficiency screw spiral extrusion winding technology. The main processes include tank extrusion winding, external welding, internal seam welding, and pipe installation. The winding thickness of PPH wrapped storage tanks can reach over 60mm, and its profile can gradually change, allowing the raw materials to be concentrated in areas with high stress, thereby significantly improving the mechanical strength and compressive capacity of the storage tanks. The body of the wrapped tank adopts a seamless design, which can avoid the risk of leakage and can be used in environments above atmospheric pressure.

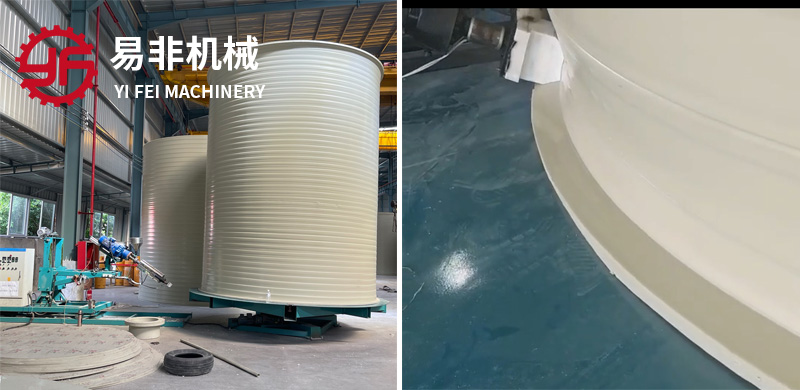

The service life of PPH wrapped storage tanks can reach up to 15 years or more, which is corrosion-resistant, environmentally friendly, and has a service life and impact resistance that is more than twice that of ordinary fiberglass compared to the fiberglass industry. It can replace metal containers such as stainless steel, nickel, and titanium in a considerable range and is an ideal new generation of high-efficiency chemical liquid corrosion-resistant storage and transportation equipment today, with low cost and good quality. The product is widely used in industries such as new energy storage, chemical, dye, pesticide, metallurgy, rare earth, machinery, power, electronics, environmental protection, textile, brewing, food, water supply, and drainage.

1гЂ?Can body extrusion winding production: The can body is a process of using PPH spiral extrusion winding unit to process PPH particles into a can body shape. The system adopts an efficient screw to melt and extrude PPH particles onto a steel mold, stacking and winding them into a tank body. Advantages of extrusion winding: в—?This machine uses efficient screw, which greatly improves the extrusion capacity в—?The product has good integrity, no seams, good corrosion resistance and leakage resistance в—?The product is flat and beautiful, which can realize the thin and thick tank body and reduce the price в—?The size and shape of the product are not limited в—?The product is processed and molded with granular materials, and has good anti-aging performance.

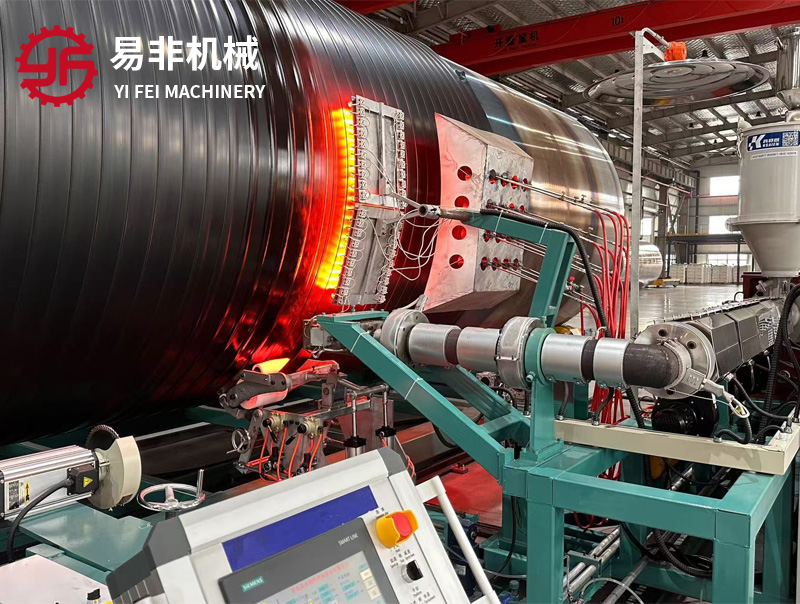

2гЂ?Disk extrusion automatic welding machine (external vertical welding production): External welding is the process of using an automatic extrusion welding unit to weld the storage tank and bottom plate into shape in one go. Hot melt the brand new PPH granular material with the same properties as the tank body at the large weld seam, integrating it with the bottom and tank body. Characteristics of bottom welding process: в—?High degree of mechanization and automation, stable product quality в—?Weld seam specifications can be designed according to the stress characteristics of the product, so as to fully utilize the integrity of the weld seam в—?Good product integrity, weld seam is integrated with the mother body, with good corrosion and leakage resistance в—?It can reduce burrs and make the seam smooth and beautiful в—?Adding ultraviolet absorbers to PPH granular material to prevent aging and extend the service life.

2гЂ?Disk extrusion automatic welding machine (external vertical welding production): External welding is the process of using an automatic extrusion welding unit to weld the storage tank and bottom plate into shape in one go. Hot melt the brand new PPH granular material with the same properties as the tank body at the large weld seam, integrating it with the bottom and tank body. Characteristics of bottom welding process: в—?High degree of mechanization and automation, stable product quality в—?Weld seam specifications can be designed according to the stress characteristics of the product, so as to fully utilize the integrity of the weld seam в—?Good product integrity, weld seam is integrated with the mother body, with good corrosion and leakage resistance в—?It can reduce burrs and make the seam smooth and beautiful в—?Adding ultraviolet absorbers to PPH granular material to prevent aging and extend the service life.

3гЂ?Long arm extrusion automatic welding machine (internal horizontal welding production): Internal welding adopts the automatic long arm extrusion welding process, which melts new PPH granular material with the same properties as the tank body at the internal weld seam, integrating it with the tank bottom and tank body. The principle and process are the same as external welding, only the equipment is different.

3гЂ?Long arm extrusion automatic welding machine (internal horizontal welding production): Internal welding adopts the automatic long arm extrusion welding process, which melts new PPH granular material with the same properties as the tank body at the internal weld seam, integrating it with the tank bottom and tank body. The principle and process are the same as external welding, only the equipment is different.

PPH/HDPE winding storage tanks are mainly used in equipment in the following industries: (1) In the new energy industry, they are mainly used for electrolyte storage and vertical storage tanks required for various production processes. (2) In the anti-corrosion and environmental protection industry, it is mainly used to produce equipment such as spray towers, transfer tanks, mixing tanks, reaction tanks, etc. for waste gas treatment. (3) In the chemical and pharmaceutical industry, it is mainly used in vertical storage tanks, measuring tanks, pickling tanks, quartz sand storage tanks, etc. (4) In the sewage treatment industry, it can be used to manufacture HMPP integrated pumping stations, horizontal storage tanks, etc.

PPH/HDPE winding storage tanks are mainly used in equipment in the following industries: (1) In the new energy industry, they are mainly used for electrolyte storage and vertical storage tanks required for various production processes. (2) In the anti-corrosion and environmental protection industry, it is mainly used to produce equipment such as spray towers, transfer tanks, mixing tanks, reaction tanks, etc. for waste gas treatment. (3) In the chemical and pharmaceutical industry, it is mainly used in vertical storage tanks, measuring tanks, pickling tanks, quartz sand storage tanks, etc. (4) In the sewage treatment industry, it can be used to manufacture HMPP integrated pumping stations, horizontal storage tanks, etc.