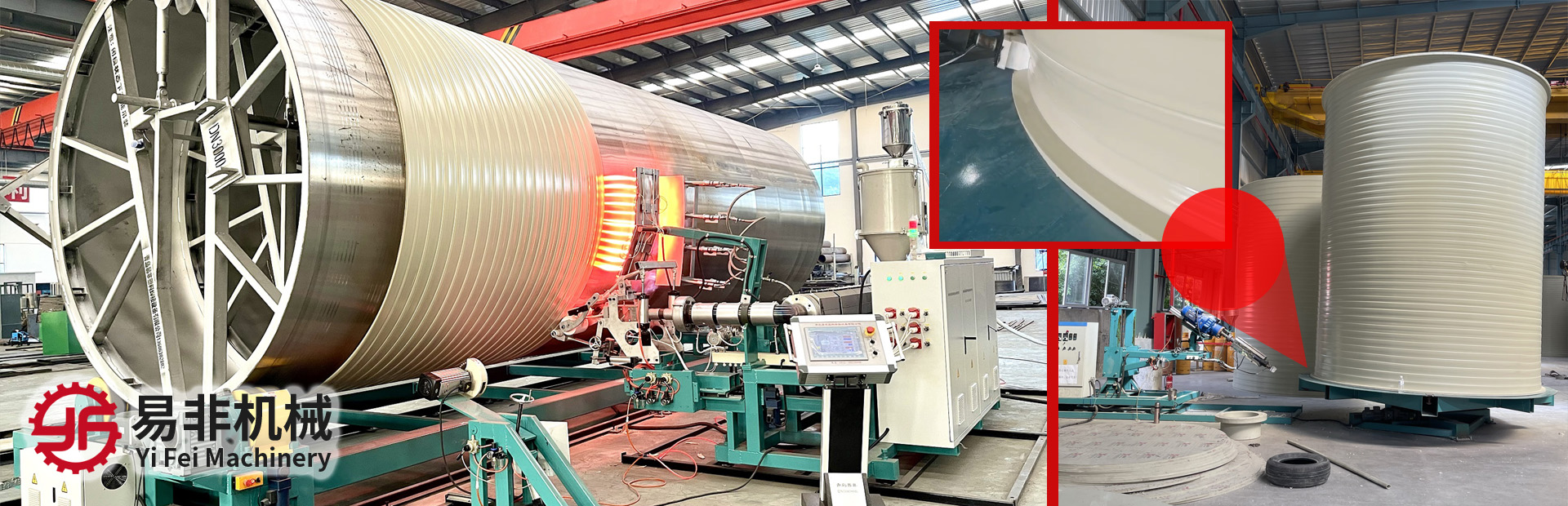

- HMPP winding storage tank production line

- PPH winding storage tank production line

- PP PE Plastic Welding Rod Production Line

- Plastic sheet production line

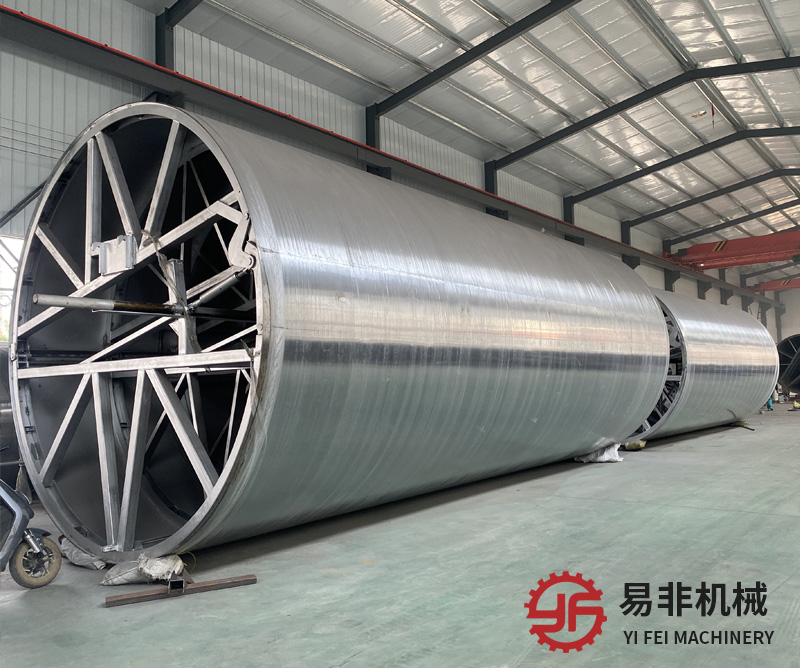

- PPH winding can mold

- PP vertebral body round head winding equipment

- Plastic sheet welding machine

- Plastic sheet bending machine

- Plastic sheet welding and bending integrated machine

- Plastic board carving machine

- Square internal and external welding automatic extrusion welding machine

- Automatic extrusion welding machine for inner and outer welding of round cans

- Plastic extrusion welding gun

- Plastic tank punching and cutting machine

The production of tank forming molds in our factory uses Q235 original flat steel for the cylinder body. The main advantages of the original flat plate are its flatness, mechanical properties, and material dimensional stability, which are higher than those of ordinary Q235 steel plates. The stress distribution within the original flat plate is uniform, and there will be no differences in load-bearing capacity in different directions of vertical length. And its load-bearing capacity is also high compared to ordinary Q235 flat plates. Therefore, our factory uses raw flat plates as the material for cylinder plates. Make the appearance and performance of the mold superior to other domestic peers.

The mold demolding production is completed by coordinating the SWL worm gear screw lift with the RV worm gear reducer. The characteristics of this device are flexible use, strong reliability, long service life, and the ability to accurately control and adjust the flatness of the mold. During operation, the transmission is smooth, the noise is low, and it saves labor and effort. The motor casing is made of aluminum alloy casting, which is lightweight and has high heat dissipation efficiency. The square tube adopts large-sized heavy-duty square tube and precision ladder type screw Special equipment for precision polishing of cylinder wall surface. The smoothness reaches level 6.3. The appearance seam of the cylinder is less than 1mm,

ŌŚ?Can process diameter of 800-4500mm, length of 6-11 meters, and mold specifications can be customized according to needs.